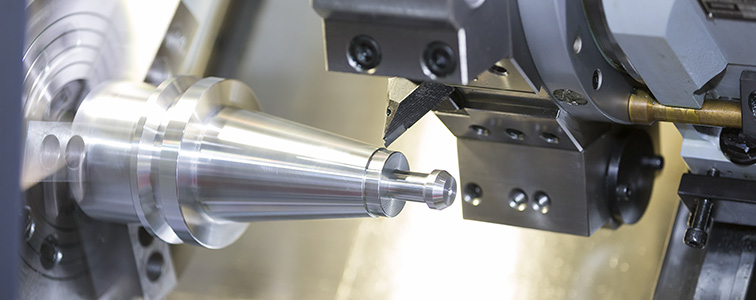

CNC Turning Service

At Premium Machining, we provide you with high quality CNC turning services using our turning mills imported from the United States. These CNC turning mills are hybrid machines, combining the best features of lathes and mills to provide true 4-axis machining for even greater efficiency and more complex geometries on your project.

When combined with our other CNC machining, low-volume manufacturing, prototyping and finishing services, you can get great parts for up to 50% less than our competitors while keeping the quality you expect and deserve.

What Is CNC Turning?

Turning involves holding the work piece in a horizontally-mounted, adjustable spindle. As the work piece rotates, various cutting tools are applied to the piece to create circular shapes and features like rings, grooves, slots, contours, radii, internal bores and threads. On our turning mills, an extra axis of movement allows us to work perpendicular to the lathe spindle for making square faces or boring holes. This opens up many new machining possibilities.

Turning is used for any rotationally symmetrical shape, to remove material quickly while leaving an excellent surface finish that sometimes requires no post-processing.

Why Choose CNC Turning?

CNC turning is the fastest way to remove large amounts of material on rounded stock. It’s also ideal for larger production runs when coupled with an automatic bar feeder that provides an uninterrupted supply of raw material into the machine.

CNC turning is the only industrial process to choose when making production volumes of concentric shapes or threaded features. And, because of the rigid construction of these machines there is little vibration, which means CNC turning can offer high levels of dimensional accuracy with excellent surface finishes.

What Kinds Of Material Can Be CNC Turned?

While potentially any solid, stable material can be turned, we work with hard plastics and aluminum, various steels, brass, copper and other alloys.Note that some hardened steels may be too hard to CNC turn, or else will require specialty cutting tools and longer processing times. Soft elastomers plastics may also be impossible to turn since they cannot be held in a fixed position or would change in shape under the pressure of the cutting tool.

How Do CNC Turning Centers Work?

Exploring the operation of CNC turning centers requires an overview of its essential components, which include:

· Chuck: Secures the bar of material for machining.

· Spindle: Rotates the chuck across axes for material shaping.

· Turret: Moves the material bar in coordination with the computer-aided design (CAD) or computer-aided manufacturing (CAM) blueprint.

· Interface: Provides the operator with options for controlling and using turning centers.

For operators, the use and operation of a CNC turning center require the following steps:

1. Upload the appropriate CAD or CAM file.

2. Stock and secure the designated material bars in the chuck.

3. Initiate the machining process via the interface or control panel.

4. Ensure the coordination between the spindle, turret and chuck.

Following the process, the operator will assess the components to ensure they are free of imperfections.

Benefits of CNC Turning Centers

With turning centers, your organization obtains several advantages, including:

· Accuracy: For many companies, the precision of CNC turning is one of its most competitive benefits. By incorporating CAD or CAM files into the process, machines can follow strict measurements and eliminate the waste of natural human errors. That can result in improvements in your finances, productivity and more.

· Flexibility: Another advantage of CNC turning centers is their flexibility for your diverse applications, as they offer a range of size capabilities. Our turning centers, for instance, come equipped in 18- to 0.5-inch diameters to match the needs of our clients, which include Fortune 500 companies.

· Repeatability: By producing product batches with unparalleled accuracy, CNC turning provides exceptional repeatability. That lets your business maximize its output and reduce its losses, which can give you the freedom to invest your capital elsewhere.

Quote:Please send your CAD files to [email protected]

Contact: ZKPTC

Phone: +8613249441199

Tel: +8613249441199

Add: Building 10, Yijunda Industrial Park, No.123, Shapu Road 2, Shapu Village, Baoan District, Shenzhen, Guangdong, China.